LabStak M20

The Alfa Laval LabStak® M20 is a flexible plate-and-frame test unit for flat sheet membranes and membrane filtration processes. It is the ideal unit for research and developmental work, quality assurance as well as pilot plant process optimization and up-scaling. The unit can be equipped with all RO, NF, UF and MF flat sheet membranes from Alfa Laval. An optional M20-2.5” housing makes the unit easily convertible also for spiral wound testing

Handy and flexible

The Alfa Laval LabStak® M20 will be your partner of choice, if dependable and reproducible results are crucial to your work.

This flexible unit is designed for plate-and-frame operation. Two external stay bolts and a low end flange with full stroke permit quick and simple alteration of the module membrane area. Any area between 0.036 and 0.72 m² (divisible by 0.036) can easily be inserted without use of additional tool.

The Alfa Laval LabStak® M20 tolerates high operation temperature and pressure and it can be equipped with the full range of flat sheet membranes available from Alfa Laval. With the optional Alfa Laval Lab M20-2.5" housing it is possible to test also spiral membranes.

Option

For the Alfa Laval LabStak® M20 we offer a specially designed Alfa Laval Lab M20-2.5" housing which can be inserted between the module flanges.

For the Alfa Laval LabStak® M20 we offer a specially designed Alfa Laval Lab M20-2.5" housing which can be inserted between the module flanges.

This special housing makes the Alfa Laval LabStak® M20 easily convertible into a spiral membrane test unit for sanitary full-fit 2.5" spiral membranes. A unique combination of plate-and-frame and spiral wound technologies in one unit.

Alfa Laval TestUnit M20

The Alfa Laval TestUnit M20 is a fully integrated system on an open and wheeled stainless steel table holding the Alfa Laval LabStak® M20 and other basic components.

The Alfa Laval TestUnit M20 is a fully integrated system on an open and wheeled stainless steel table holding the Alfa Laval LabStak® M20 and other basic components.

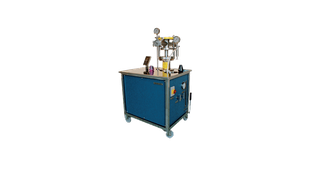

Alfa Laval LabUnit M20

The Alfa Laval LabUnit M20 is a fully integrated system contained in a closed and wheeled cabinet holding the Alfa Laval LabStak® M20 and other basic components.

The Alfa Laval LabUnit M20 is a fully integrated system contained in a closed and wheeled cabinet holding the Alfa Laval LabStak® M20 and other basic components.

Benefits

- flexible membrane areas from 0.036 m² to 0.72 m²

- simultaneous test of different membrane types

- option to test spiral membranes

- easy exchange of spiral and flat sheet membranes

- separate permeate outlet from each individual membrane pair

- high operating temperature and pressure

- variation of cross-flow from 3.5 to 24 l/min.

- compact and space-saving design

- all components in compliance with FDA and EEC regulations, allowing use within food and pharmaceutical processing applications

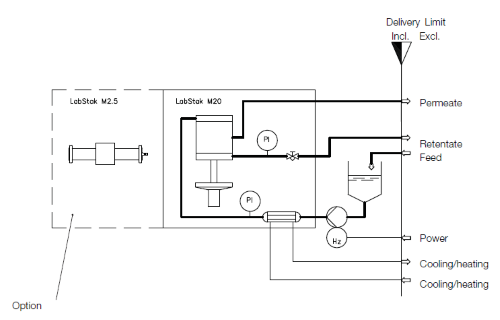

動作原理

Flow diagram of Alfa Laval LabStak® M20

Physical separation

Membrane filtration is a physical separation process in which the driving force is the difference in pressure between the two sides of a special membrane. This process is characterized by the ability to separate molecules of different sizes and characteristics.

Almost all industrial membrane filtration is carried out as cross-flow filtration, where the liquid being filtered flows parallel to the membrane at high velocity and under pressure.

Physical barrier

In its most basic terms, membrane filtration involves passing a single feed stream through a membrane system that separates it into two individual streams, known as the permeate and the retentate. The membrane that separates them is a physical barrier with highly specialized characteristics - a barrier that only certain selected components in the feed stream can pass through.

Passing through

The pores of such membrane material are so small that they are measured in Angstrom (10-10 m), and pressure is required to force the liquid through them. In fact, the pores in the membranes used for nanofiltration and reverse osmosis are so small that they cannot be seen even with a scanning electron microscope.