MF flat sheet

The selection of microfiltration flat sheet membranes from Alfa Laval covers different pore sizes and flux properties. The membranes are used in an extensive range of processes applied in the food, beverage, dairy, biotech and pharmaceutical industries

Alfa Laval offers two series of microfiltration (MF) membranes with different flux properties, pore sizes and rejection capabilities. The membrane materials are either polysulphone or fluoro polymer based on a unique construction on polypropylene (PP) support material which provides optimum cleaning conditions.

MFG series

The MFG microfiltration membrane is made of polysulphone polymer. The membrane is available in the types MFG1 having a pore size of 0.1 µm and MFG2 with a pore size of 0.2 µm.

MFP series

The MFP microfiltration membrane is made of fluoro polymer. The membrane is available in the types MFP2 (pore size 0.2 µm) and MFP5 (0.5 µm).

Benefits

- cover a broad spectrum of flux properties, pore sizes, molecular weight cut-off values and rejection capabilities

- available by the metre, as standard 20 x 20 cm sheets or cut into flat sections to fit into all Alfa Laval plate-and-frame module configurations

- delivered with necessary lock and passage rings

- suitable for extensive range of processes

- manufactured by Alfa Laval's own membrane centre

動作原理

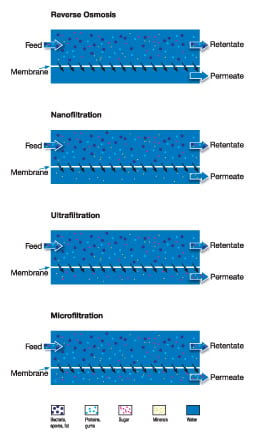

Reverse osmosis (RO)

RO uses the tightest possible membrane in liquid separation. In principle, water is the only material that can permeate the membrane. All other materials (salts, sugars, etc.) will be unable to pass through.

Nanofiltration (NF)

NF is not as fine a separation process as reverse osmosis, and uses membranes that are slightly more open. Nanofiltration allows small ions to pass through while excluding larger ions and most organic components.

Ultrafiltration (UF)

UF involves using membranes in which the pores are larger and the pressure is relatively low. Salts, sugars, organic acids and smaller peptides are allowed to pass, while proteins, fats and polysaccharides are not.

Microfiltration (MF)

In MF, suspended solids, bacteria and fat globules are normally the only substances not allowed to pass through.

コンプライアンス

アルファ・ラバルの膜の製造に使用されるすべての材料は、スパイラル巻き膜と平板膜の設計と構成の両方で、EU 規制 (EC) 1935/2004、EU規制 10/2011、EU規制 (EC) 2023/2006 、および FDA 規制 (CFR) タイトル 21に準拠しています。したがって、この膜は食品や医薬品の加工用途での使用に適しています。

これらの準拠は、プレートとフレームのユニット、エレメントのハウジング、ポンプなどの品目を含む、膜の操作に関連する機器や付属品にも適用されます。

洗浄性

ほとんどの種類のダイアグラムは、ポリプロピレン製の材料の上に張り合わされているため、高温や高い水素イオン濃度に耐えることが可能です。

これらのいわゆる pHt 膜タイプは、高温で連続的に動作することができ、pH 値 1 ~ 13 の範囲での高温 (75℃) 洗浄にも耐えることができます。