Gas heat recovery heat exchangers

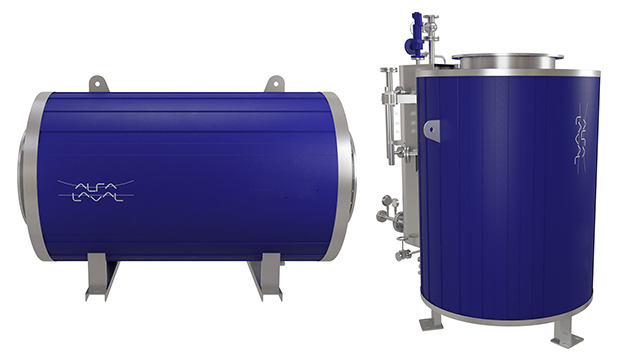

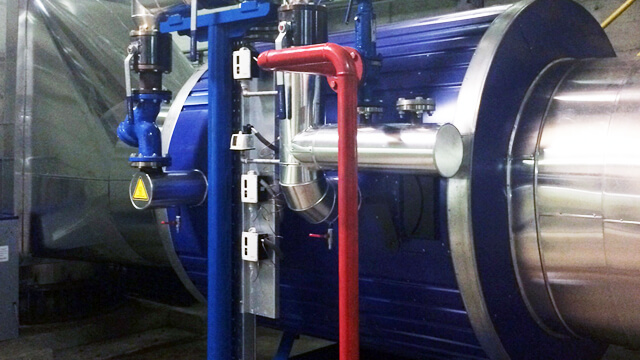

The Alfa Laval GHR is a compact gas heat recovery heat exchanger especially designed for exhaust heat recovery from small and medium gas engines, turbines and clean process flue gases up to 600°C. Approximately 25% of the overall industrial waste heat worldwide falls within the range of 200-500°C. By utilizing Alfa Laval GHR, energy efficiency will be enhanced through the recovery and reduction of exhaust heat.

Features that make recovery different:

- Lower footprint and weight due to the extended heat transfer area.

- No external bypass is needed. Robust in terms of many starts/stops due to “Spring Design”.

- Cleaning is possible during the operation of the gas engine, turbine, or process via an integrated cleaning device.

- Media output can be adjusted according to the need due to the integrated regulation damper.

- Low inertia due to low holdup volume of media. Increase uptime and reduce major cleaning intervals via dry-run mode.

Why turn to Alfa Laval for exhaust heat recovery?

Energy Saving

Alfa Laval GHR heat exchangers provide the best overall performance in excess flue heat recovery. Approximately 22 to 25% of excess heat from exhaust flue gases from the engines and turbines has been reused. Expect up to 95% improvement in plant efficiency in combined heat and power applications.

It captures exhaust clean process flue gas heat from the various sources of industry and generates hot water, steam or hot oil that can be a free utility for the industry. It also generates electricity via ORC from the excess heat of utility.

Increase Profitability

Alfa Laval GHR heat exchanger recaptures the maximum energy possible and hence reduces fuel consumption, which results in the shortest payback time for investment. Often less than a year depending on project specifications.

Plug & play module will reduce installation time. Due to its compact size, lower footprint, and weight, it requires less space in the plant.

Cleaning of equipment is possible during the operation of engines and turbines. Which reduces downtime.

Emission Reduction

Improving efficiency at existing plants by recovering exhaust heat anywhere in the world is a path of no regret. Making efficiency improvements at existing plants is an effective and economical way of reducing carbon dioxide (CO2) emissions. A more efficient plant uses less fuel, has lower emissions, and experiences lower variable costs. Alfa Laval GHR heat exchangers can improve the efficiency of plants and hence reduce emissions, including CO2, and improve plant performance.

Alfa Laval GHR heat exchangers in numbers

- 1000 units of Alfa Laval GHR heat exchangers are installed across the globe.

- 2.0 GW of installed excess heat recovery across the globe.

- 90% plant efficiency possible in combined heat and power applications.

- 1-year return on investment (ROI) is possible in the best cases.

CHP

Combined heat and power (CHP) is one of the most efficient methods of energy utilization. Over 90% of energy can be channelled back into efficient use. It is a highly cost-effective solution that brings many benefits.

Organic Rankine Cycle

Renewable energy not only spurs growth, but also bodes well for a more sustainable future. Power generation using geothermal energy or industry waste heat streams can boost plant output, improve your environmental footprint, and increase profitability.

Excess heat recovery

Excess heat recovery is critical to improving energy efficiency. Today, technology makes it possible to capture and reuse the excess heat from existing processes for other purposes, such as heating or generating electricity.

Technical data of GHR

- Capacity: 250 kWe – 10 MWe

Exhaust flue gas side:

- Maximum inlet temperature: 600 Deg C

- Minimum outlet temperature: dependent on engine fuel and exhaust gas composition

- Pressure loss: according to customer requirements

Media sources

Hot water

- District heating, HVAC, process applications, ORC (electricity) etc.

TEG

- District heating, HVAC, process application, ORC (electricity) etc.

Thermal oil

- Heating

Steam

- Process applications, steam turbines (electricity), service steam

Exhaust Heat Source and ORC

Selected recovery references

Power generation in China

70 x Alfa Laval GHR after gas engines to produce hot water.

Process flue gas in China

3 x Alfa Laval GHR 406 and 2 x Alfa Laval GHR 410 used to recover exhause flue gas heat from aluminium melting furnace to generate hot water.

Industrial process in Italy

Alfa Laval GHR 814 for hot water application after gas engine.

Hotel industry in Mexico

Alfa Laval GHR 210 for hot water application after gas engine.

District heating in Denmark

Alfa Laval GHR 714 for hot water application after multi fuel engines.

排熱回収

適切な熱交換器技術を使用することで、産業プロセスによって生成される高温熱、ならびにデータセンターの冷却や水処理アプリケーションなどでヒートポンプによって捕捉される低温熱を回収することができます。この熱は、地域暖房から電力生成に至るまでの幅広い用途に利用することが可能です。