Optimizing dry rendering processes for 40% in energy savings and improved protein and fat quality and yields

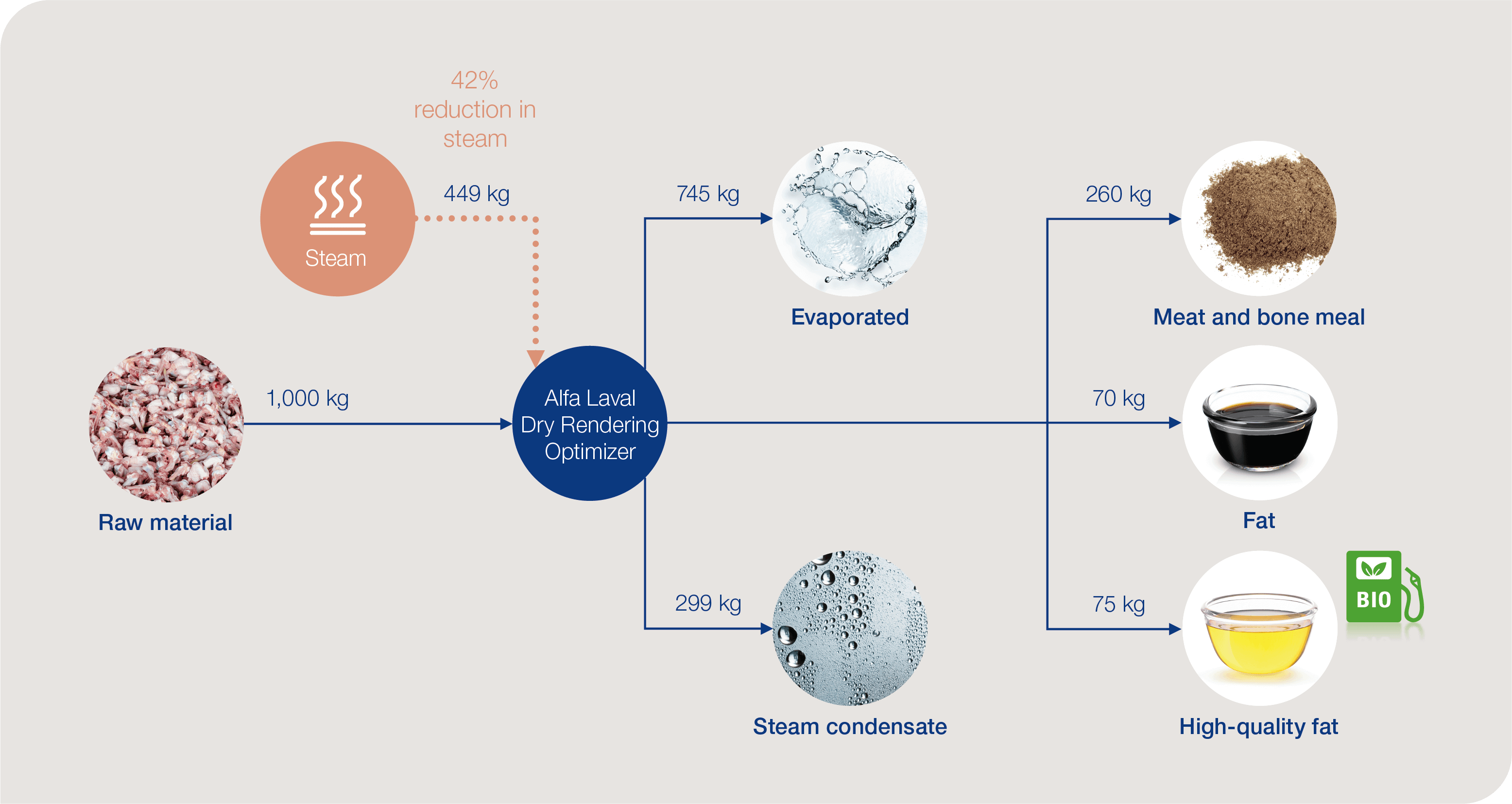

Fat and meat and bone meal producer Proteg SpA approached Alfa Laval to improve product quality while reducing energy costs and environmental emissions. The request? A higher protein content to raise the sales price of protein meal for pet food and higher quality fat for use in biofuel, which translates into higher yield. The solution? Adding the Alfa Laval Dry Rendering Optimizer, a highly efficient, cost-effective system, to the existing dry rendering process lines, increasing protein content in meal by 3–5% and fat yield by more than 10% while reducing energy costs by 40%

DATE 2024-01-18

Process expertise at work

Established in the 1940s, the family-owned company based in Naples, Italy, is a leading rendered products manufacturer that transforms animal by-products and slaughterhouse waste into valuable products for pet food and renewable fuels. Alfa Laval invited Proteg to visit its Denmark office to take advantage of its process expertise and the rendering plants at a multi-national U.S. protein provider to see Alfa Laval’s expertise and equipment at work.

Solid partnership for hybrid rendering plant conversion

Proteg was satisfied with the company’s ongoing collaboration with Alfa Laval, including bringing a meat rendering facility with key Alfa Laval components into service eight years ago and continually optimizing

operations. “Seeing is believing,” says Salvatore Papa, General Manager, Proteg. “We were impressed by what we saw during our site visits to the U.S. and what we learned in Denmark when discussing our needs with the Alfa Laval food processing experts.”

Cut operating costs by 40% with optimization and automation

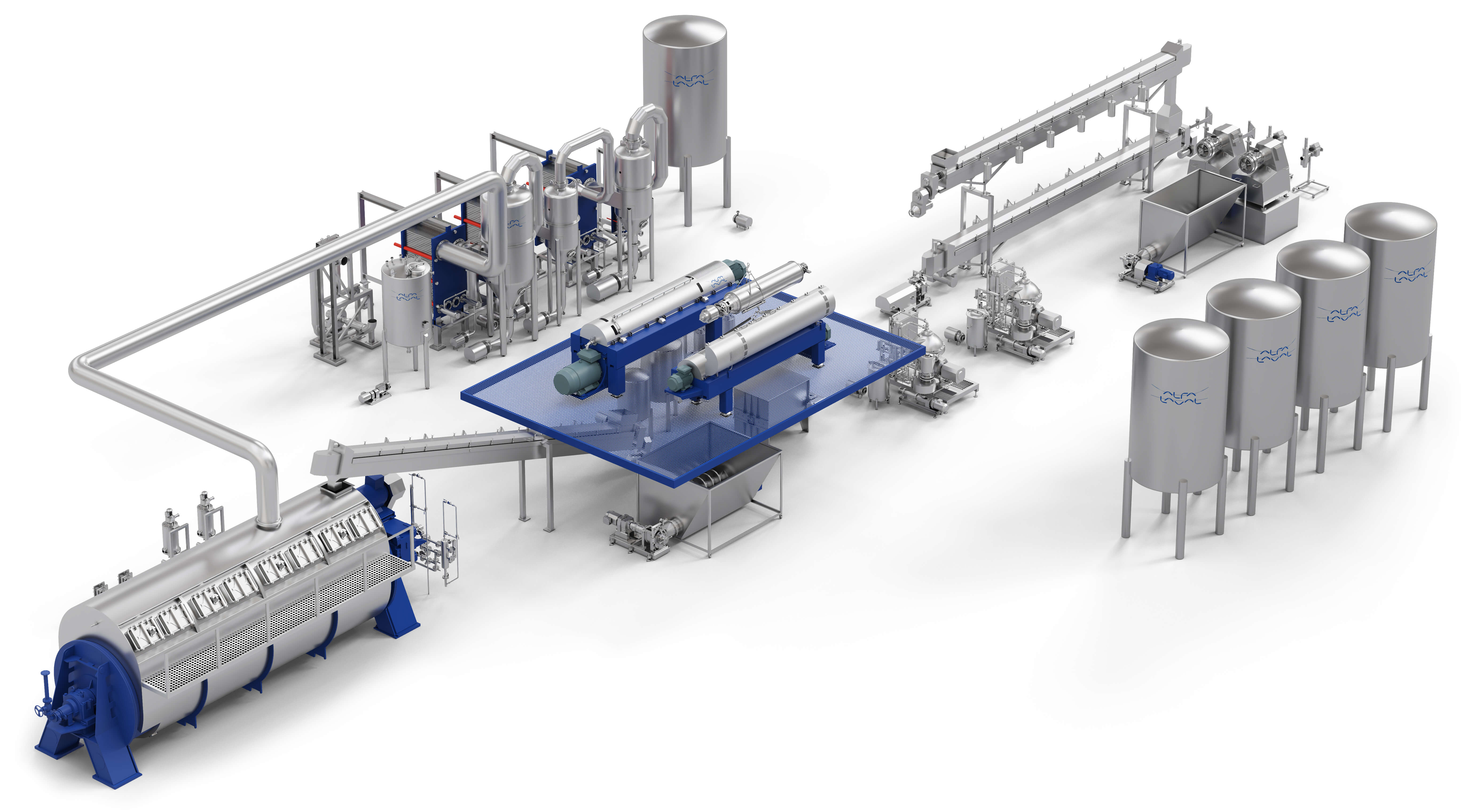

Based on its 20-year business relationship with Alfa Laval, Proteg decided to enhance its dry rendering plant with the Alfa Laval Dry Rendering Optimizer, a continuous wet rendering plant to recover higher quality protein meals and increase the output of high-purity fat for renewable fuels. The expanded facility processes 10 tons per hour of meat by-products typically comprised of 60% bone and 40% soft tissue.

Introducing Alfa Laval automation systems to manage the dry rendering process contributed to a 40% reduction in operating expenditures. Automation frees up highly skilled employees from the time-consuming, data-intensive tasks of manually setting and resetting parameters on critical equipment. Instead, Proteg put employee expertise to good use, doing what they do best, or provided upskilling to more useful engagements, boosting employee satisfaction.

Energy savings of 40% and up to 5% higher protein content in pet food

Converting processing lines from dry rendering to wet rendering reduced energy costs by 40% and enhanced

product quality, increasing protein content by up to 5%. Investing in automation for wet rendering helped accelerate production and reduce operating expenses, boosting both yield and revenues.

Better protein meal stability and an increase in fat yield of more than 10%

Transforming meat by-products into valuable high purity fat and protein meal generates more revenue for Proteg and contributes to reaching its sustainability goals. Converting the dry rendering plant to a wet rendering plant improved yield by more than 10%.

99.8% pure fat with optimal colour and moisture content

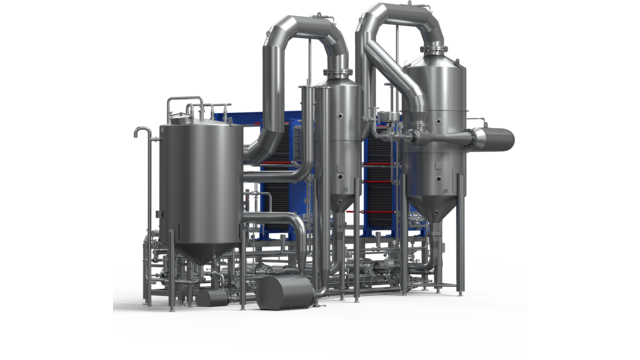

High fat content in the meal poses the risks of product degradation and an unpleasant taste or smell. The Alfa Laval wet rendering system increased the stability of the protein meal by removing about 50% of the residual fat compared to conventional rendered meat and bone meals. Moreover, the energy-efficient, non-fouling Alfa Laval evaporation system uses downstream waste heat to concentrate the water-soluble protein in the stickwater phase. Concentrating the stickwater before drying reduces the need to generate fresh process steam.

Combining the solid phase from the decanter with the concentrated stickwater and drying it in a disc dryer to generate waste heat steam greatly reduces the heat required for the process system. After the dryer, a cooler reduces the temperature of the meal to ambient temperature for storage stability. The protein meal quality has a higher market value due to the high protein content in the meal and very low content of fat. It is also possible to increase the moisture content of the protein meal as needed.

90% savings in fat refining costs and higher purity fat

The Alfa Laval Dry Rendering Optimizer makes it possible to obtain high-purity fat for use in biofuel without chemical refining treatments, like neutro-degumming, required for typical dry rendering fat. Savings in fat refining costs are therefore cut by 90%, according to Proteg. The quality of the fat produced is essentially phosphorous-free. Like the high-quality protein in the meal produced, the extracted fat also has a higher market value, generating more revenue for Proteg.

We are always collaborating with Alfa Laval to fine-tune operations. We look forward to continuing our close and constructive partnership and using Alfa Laval know-how to tailor solutions to meet our requirements.

Global expertise, local support

With decades of experience in refining fats and oils, Alfa Laval has been addressing oils and fats refining for the food industry for decades. As a global supplier of heat transfer, separation, and fluid handling solutions, Alfa Laval is committed to providing Proteg with ongoing process engineering expertise and support as their processing requirements evolve to keep pace with demand.

ハイライト・テクノロジー

エネルギー節約

Converting processing lines from dry to wet rendering reduced energy costs by 40%.

Cost savings

Automation reduced operating costs by 40%. Eliminating chemical refining treatments cut fat refining costs by 90%.

Increased revenues and reduced emissions

• Up to 5% higher protein content

• 99.8% pure fat with optimal colour and moisture content

• Better protein meal stability

• Fat yield increase of more than 10%