Construction drilling

Urban growth is a key driver of the increased need for construction drilling projects. However, working in urbanized areas can be tricky with tight spaces, strict regulations and waste and noise requirements. Alfa Laval’s solutions for solids removal and sludge dewatering can help with these issues, meeting the standards set by the regulations in a footprint small enough to meet your needs. This increases your ability to compete economically, effectively, and safely.

Robust compact equipment to help you lead the field in muck cleaning

- Fully customisable, cost effective wastewater treatment

- High volume capacities and compact equipment design

- Contained process resulting in good and safe working conditions

- Improved sustainability benefits – less waste, less transport, less cost

- High level of automation – minimum operator intervention

Alfa Laval construction decanter centrifuges can be optimized in every detail to ensure the best separation of drilling solids for your needs. Robust and low maintenance compared to other separation technologies, they are perfect for operations in Horizontal Directional Drilling (HDD), Tunnel Boring (TBM), Drill and blast tunnels and Exploration drilling. Compact and easy to use they make your operation environmentally sound, more economical and intrinsically safer. Continuous operation captures all the waste while reducing its weight. Decanters are a viable, tested complement or even better alternative to belt filter and frame filter presses, and enabling you to boost capacity and raise yields.

Dewatering drill slurries

Light, reliable and compact, Alfa Laval decanter centrifuges meet the tough separation demands of dewatering drill slurries head on. Increased drilling speed and less waste are just two of the benefits our decanters provide.

Construction waste water treatment

Tough requirements call for tough solutions. Alfa Laval decanter centrifuge delivers where you need it most. Effective separation down to a particle level meet the requirements for reusing or disposal of water. All in a smaller footprint and with less maintenance needs than other technologies.

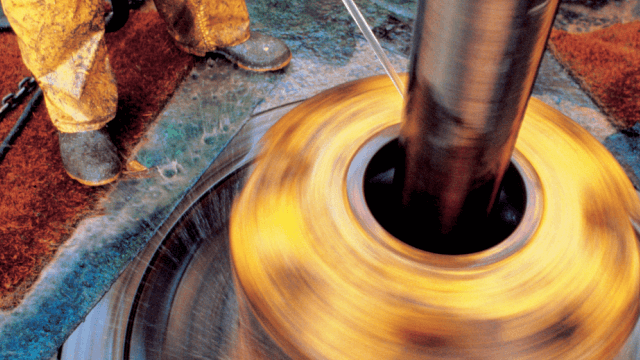

Mixing drill slurries

Properly mixing drilling slurry is an important part of making the drilling process more effective, faster and less costly. Alfa Laval Vortex Shear-Mixers and Vortex Radial Eductors offer premium mixing results more quickly than other mixing technologies while reducing slurry additive waste and downtime.

Download our whitepaper!

Discover how to increase your sustainability footprint, while saving on waste costs.

Innovative technology for civil drilling

Alfa Laval decanter centrifuges are key to achieving high efficiency in drilling and tunnelling, especially in terms of treatment of slurries and water cleanliness. The technology efficiently removes most of the fine particles that traditional slurry treatment equipment cannot without resorting to polymer use. Specifically designed for construction sites and tunnelling environments, the Alfa Laval decanter centrifuges excel at handling abrasive and coarse particles and can process large volumes of feed solids and various flow rates.

The decanter centrifuges are available with a range of modules ideally suited for every kind of solids separation job. They range from fully automated operation to simple “hands-on” capabilities. Whichever you choose, you can look forward to effective solutions to your separation needs for many years.

How it works - decanter

The rotating assembly is supported on a compact welded box beam frame with main bearings at both ends. The in-line main motor is flange- or foot mounted onto the unit with adjustable brackets for belt tension adjustment. The bowl is driven at the conical end by an electric motor with a V-belt transmission. The bowl, conveyor, casing, inlet tube, outlets and other parts in contact with the process media are made of AISI 316 or duplex stainless steel with tungsten carbide inserts in the areas most susceptible to wear.

Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. The feed enters the bowl through a stationary inlet tube and is accelerated smoothly by an inlet rotor. Centrifugal forces cause sedimentation of the solids on the wall of the bowl. The conveyor rotates in the same direction as the bowl, but at a different speed, thus moving the solids towards the conical end of the bowl. The design enables the decanter to scroll out high loads of solids without blockages caused by high levels of dryness. Only the very driest fraction of the sludge cake leaves the bowl through the solids discharge openings into the casing.

The decanter centrifuge can be adjusted to suit specific requirements by varying the bowl speed, the conveying speed, the pond depth and the feed rate

Product portfolio

LYNX construction drilling decanter

Alfa Laval LYNX centrifugal decanter systems are made for muck handling. They efficiently remove solid particles from water and oil-based slurries resulting in better penetration rates, shorter drill times, less wear on key components as well as longer sludge service life. It also reduces chemical usage as well as drill waste, which contributes to lower disposal and waste water treatment costs.

Normally installed in a bypass system, our LYNX centrifugal decanters operate continuously without interrupting drilling operations. The range can handle muck flow rates from 5 m3/hour up to 100 m3/hour. The variable bowl speed ensures the right G force required for the most efficient separation while the conveying speed can be adjusted for optimal balance between liquid clarity and solids dryness. The adjustable pond depth also contributes to the best balance between clarity and dryness.

Product information LYNX

Ease of operation and high uptime

- Developed specifically for the tunnel boring and construction industry

- Small footprint – easy installation and mobilization

- Continuous and automatic operation with option of remote surveillance

- High separation efficiency – clean slurry improves drill penetration rate

- Highly sustainable cleaning capacity – less waste due to dry cake and reused slurry

Stay ahead, save costs and boost sustainability

If you are looking for ways to raise profitability and meet ever more stringent environmental requirements in drilling and tunnelling operations, contact Alfa Laval today to learn more about how our proven, sustainable muck cleaning solutions can save you money and take your business to new levels of excellence.