A series

Alfa Laval’s comprehensive range of separators for the dairy industry includes our unique technology for anhydrous milk fat production (AMF). The A Series of hermetic separators provide an efficient, reliable and cost-effective separation solution.

Advanced technology for anhydrous milk fat processes

- Alfa Laval’s unique, bottom-fed, Hermetic Design™ provides premium oil purification efficiency for maintaining a high product quality

- The bottom-fed design reduces shear forces for gentle product treatment with a minimum level of emulsification

- Hermetic seals on inlet and outlet prevent oxidation

- Easy adaptation to process conditions provides increased production flexibility and efficient CIP

- Energy savings of up to 60% thanks to the Hermetic Design

Achieving high product quality in anhydrous milk fat processing

Purification of anhydrous milk fat, or butteroil, is a niche application within dairy processing where our technology brings value to the process. In addition to preventing oxygen pick-up and preserving product quality, our unique, bottom-fed Hermetic Design™ gives you high separation efficiency, low energy consumption and superior process flexibility.

The Alfa Laval A Series separators are expertly designed for processing anhydrous milk fat, making them ideal for butter and spread production.

Saving energy, cutting costs

Alfa Laval separators with Hermetic Design are the most energy-efficient on the market. When our unique eMotion technology is added, minimized air friction brings additional power reduction. Combined, our unique design and technologies can deliver up to 70% energy reduction compared to non-hermetic alternatives on the market.

Sustainable is our standard

Alfa Laval wants to help dairy producers make optimal use of every resource in their process. That’s why we build high-efficiency dairy separators that prevent product waste while consuming less energy and water, thanks to unique innovations. Letting you deliver top-quality products that leave a smaller environmental footprint.

最新の分離機の機能

アルファ・ラバルの分離機が他と違うのは、その構造・設計にあります。特許を取得した独自の幅広い技術により、乳製品の品質向上と高いサニタリー性を実現します。また、水とエネルギーの消費量を大幅に削減し、ランニングコストと環境負荷の両方を低減することも可能です。

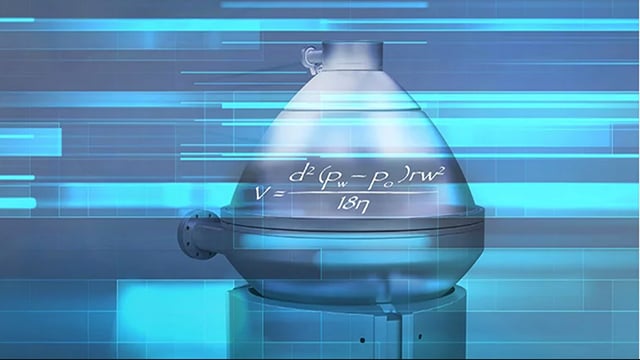

Hermetic Design™

Gentle acceleration, powerful efficiency

A unique air-tight bowl that enables improved product quality and drastically reduces power consumption.

eDrive™

Mechanical simplicity for higher efficiency and lower costs

A direct-drive system with fewer rotating parts that minimizes both maintenance and energy costs.

UniDisc™

New levels of capacity and hygiene

A radical new disc design that decreases cleaning needs while increasing flow rate by up to 20%.

eMotion™

Double the output per kWh

An innovation to minimize friction, which cuts the separator´s energy consumption and CO2 footprint by up to 70%.

Bactofuge®

Outstanding solids capacity

Continuous solid discharge ensures an intact and highly concentrated stream for onward processing or as a valuable by-product. This makes it possible to increase separation capacity.

Separators for every application

Alfa Laval was born from the invention of the modern milk separator. Today, we cover the full scope of dairy separation applications. With unique innovations to increase profitability and sustainability in your process, no matter your product. Check our full portfolio!

次の分離ソリューションのテスト、検証、およびスケールアップ

生産ラインのアップグレードや概念実証の実施に関わらず、Alfa Lavalは適切なセパレータソリューションを自信を持って選択するお手伝いをします。お気軽にお問い合わせいただければ、テストセンターでの相談や試験の手配、または現場でのテスト用のユニットのレンタルについてご案内いたします。

Contact us to find our dairy partners

Alfa Laval separation equipment plays a critical role in all types of dairies, in all parts of the world. To best serve this market, we work with Tetra Pak as our Global Alliance partner and other selected process integrators in selected regions. Please contact us to connect to an Alfa Laval partner in your region.

分離機について

アルファ・ラバルの創業者が19世紀に世界で始めて遠心分離機を実用化して以来、100年以上にわたって様々な産業やプロセスに分離技術においてイノベーションを進めてきました。こちらのページでは、分離機の原理や構造、分離技術の種類や役割に関する様々な情報を発信しています。